Call: 07971550511

à¤à¥à¤°à¤¿à¤®à¤¿à¤à¥à¤¸ फ़à¥à¤²à¥à¤°à¤¿à¤à¤ मशà¥à¤¨

About à¤à¥à¤°à¤¿à¤®à¤¿à¤à¥à¤¸ फ़à¥à¤²à¥à¤°à¤¿à¤à¤ मशà¥à¤¨

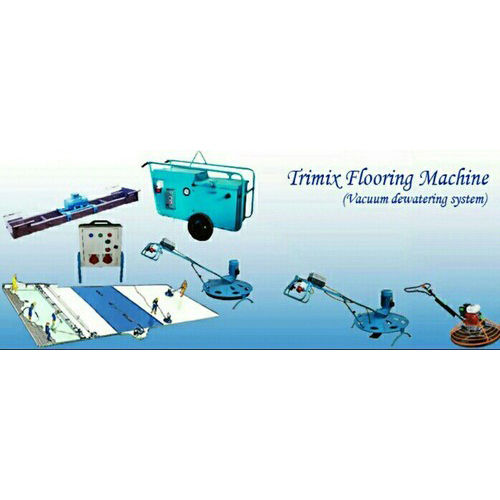

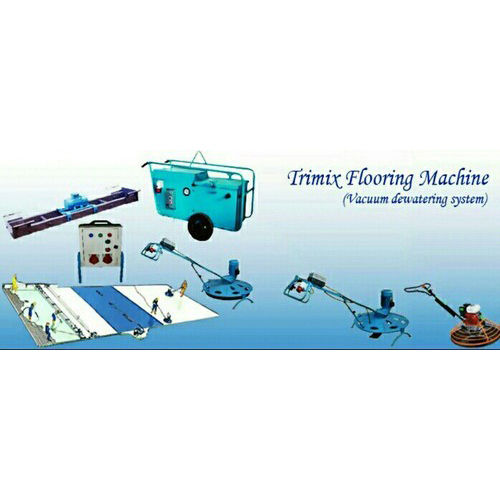

Highlighted for its formidable performance and impeccable reliability, the Trimix Flooring Machine stands as a paragon of concrete finishing. Get it Now and experience superior results, with the power to personalise your flooring requirements. Available in both single and three phase options, its robust 3 HP motor and heavy-duty steel frame effortlessly trowel up to 150 mm thick concrete. Featuring a 900 mm trowel diameter, adjustable speed, and air-cooled cooling system, this machine is indispensable for exporters, manufacturers, service providers, and suppliers across India seeking efficiency and excellence.

Trimix Flooring Machine: Application and Usage

This Trimix Flooring Machine is widely used in large industrial floors, warehouses, commercial complexes, and parking areas. Its advantage lies in delivering high-performance concrete finishing with rapid and uniform results. With usage suited for both new constructions and renovation projects, professionals rely on its heavy-duty reliability and adjustable speed controls to achieve optimal surface smoothness and durability, regardless of application scale or floor size.

Packaging, Certifications, and Supply Details

Every machine arrives professionally packed to ensure safe shipment. We offer globally recognized certifications attesting to its quality and safety standards. Able to be shipped in bulk or per order, our supply ability meets demanding project schedules, making sure you receive this trusted equipment promptly. Choose us for timely delivery, secure packaging, and an assured experience from the moment your order is shipped.

Trimix Flooring Machine: Application and Usage

This Trimix Flooring Machine is widely used in large industrial floors, warehouses, commercial complexes, and parking areas. Its advantage lies in delivering high-performance concrete finishing with rapid and uniform results. With usage suited for both new constructions and renovation projects, professionals rely on its heavy-duty reliability and adjustable speed controls to achieve optimal surface smoothness and durability, regardless of application scale or floor size.

Packaging, Certifications, and Supply Details

Every machine arrives professionally packed to ensure safe shipment. We offer globally recognized certifications attesting to its quality and safety standards. Able to be shipped in bulk or per order, our supply ability meets demanding project schedules, making sure you receive this trusted equipment promptly. Choose us for timely delivery, secure packaging, and an assured experience from the moment your order is shipped.

FAQs of Trimix Flooring Machine:

Q: How can the Trimix Flooring Machine be used in large construction projects?

A: The Trimix Flooring Machine is designed for high-capacity concrete finishing, making it ideal for expansive industrial buildings, warehouses, and commercial areas where uniform and smooth flooring is crucial.Q: What are the main benefits of using a Trimix Flooring Machine?

A: Key benefits include rapid finishing, adjustable trowel speed for custom surface results, improved surface durability, and the ability to handle concrete thicknesses up to 150 mm with consistent quality.Q: When should I consider deploying a Trimix Flooring Machine?

A: You should deploy the machine during the final phase of concrete laying, once the initial setting has begun but before complete curing, to achieve a smooth and durable surface.Q: Where can I get the Trimix Flooring Machine shipped?

A: The machine can be shipped across India and to international destinations for exporters, manufacturers, suppliers, and service providers based on your requirements.Q: What is the process for adjusting trowel speed on the Trimix Flooring Machine?

A: The trowel speed can be customized between 60125 RPM using the built-in controls, enabling the operator to tailor surface finishing according to project needs.Q: How do certifications ensure the quality of the Trimix Flooring Machine?

A: Certifications assure buyers that the machine meets industry standards for performance, safety, and reliability, confirming its suitability for rigorous professional use.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

अधिक Products in ट्रिमिक्स फ़्लोरिंग मशीन Category

वैक्यूम डाई वॉटरिंग सिस्टम

मूल्य या मूल्य सीमा : आईएनआर

न्यूनतम आदेश मात्रा : 1000

माप की इकाई : , ,

जांच भेजें

जांच भेजें

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese